Abstr:AC2-12: Difference between revisions

(Created page with "blah") |

m (Dave.Ellacott moved page Lib:AC2-12 to Abstr:AC2-12) |

||

| (9 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{ACHeader | |||

|area=2 | |||

|number=12 | |||

}} | |||

__NOTOC__ | |||

=Turbulent separated inert and reactive flows over a triangular bluff body= | |||

==Application Area 2: Combustion== | |||

===Application Challenge AC2-12=== | |||

=Abstract= | |||

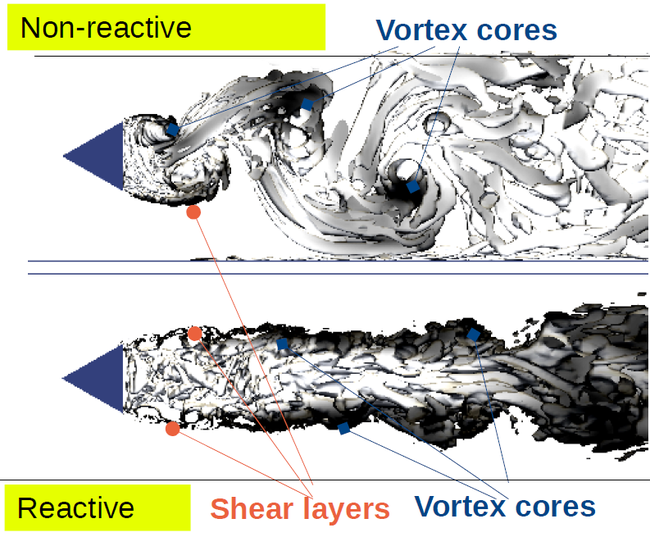

This test case concerns the dynamics of nonreactive and reactive bluff-body wake flows. The test conditions can be described by the Reynolds number (based on the bluff-body base), Re = 28,000 – 47,000, which is in the sub-critical flow regime. The key features of the flow mechanics for this Reynolds number range are the laminar boundary layer, separated shear layer, wake and the flow instabilities (the absolute and convective), which lead to complex, nonlinear interactions between them. For the reactive cases, the flame (and the turbulence-chemistry interaction) introduces additional physics by effects of exothermicity and flow dilatation on the flow field, which leads to large differences between the non-reacting and the reacting wake. | |||

Here, combustion is characterized by the lean, premixed propane-air mixture of equivalence ratio, | |||

φ = 0.6 – 0.65 (“thin reaction zone” regime). Several studies point out that turbulence levels in the reacting flow are much lower than in the non-reacting case, particularly in the vicinity of the recirculation zone, which can be explained by the stabilization of the convective instability, increased viscosity in the post-flame gases and the vorticity sink induced by the gas expansion. | |||

The experiments for the present test case have been carried out by the Volvo Company. The Validation Rig consists of a straight channel, divided into an inlet section and a combustor section. Triangular bluff-bodies were used for flame stabilization. | |||

The simplicity of the geometry makes this test case an ideal platform for validation and verification of different numerical methods and mathematical models. A series of numerical simulations undertaken to study both non-reacting and reacting bluff-body flows are reported here. The purpose is to assess the applicability of different turbulence and combustion (turbulence-chemistry interaction) models to capture the unsteady (combustion) physics. Heat transfer effects are investigated as well. Different calculation approaches like RANS/URANS, LES and hybrid RANS/LES (SAS) and different turbulence models are compared. Results obtained by several turbulence-chemistry interaction models like TFC and EDC are compared and discussed as well. | |||

<div id="figure0"></div> | |||

{|align="center" border=0 | |||

|- | |||

|align="center"|[[Image:AC2-12_fig0.png|650px]] | |||

|- | |||

|align="center"|Schematic view of the flow mechanics of the non-reactive and reactive bluff-body flows. | |||

|} | |||

<br/> | |||

---- | |||

{{ACContribs | |||

|authors=D.A. Lysenko and M. Donskov | |||

|organisation=3DMSimtek AS, Sandnes, Norway | |||

}} | |||

{{ACHeader | |||

|area=2 | |||

|number=12 | |||

}} | |||

© copyright ERCOFTAC 2019 | |||

Latest revision as of 11:13, 16 August 2019

Turbulent separated inert and reactive flows over a triangular bluff body

Application Area 2: Combustion

Application Challenge AC2-12

Abstract

This test case concerns the dynamics of nonreactive and reactive bluff-body wake flows. The test conditions can be described by the Reynolds number (based on the bluff-body base), Re = 28,000 – 47,000, which is in the sub-critical flow regime. The key features of the flow mechanics for this Reynolds number range are the laminar boundary layer, separated shear layer, wake and the flow instabilities (the absolute and convective), which lead to complex, nonlinear interactions between them. For the reactive cases, the flame (and the turbulence-chemistry interaction) introduces additional physics by effects of exothermicity and flow dilatation on the flow field, which leads to large differences between the non-reacting and the reacting wake. Here, combustion is characterized by the lean, premixed propane-air mixture of equivalence ratio, φ = 0.6 – 0.65 (“thin reaction zone” regime). Several studies point out that turbulence levels in the reacting flow are much lower than in the non-reacting case, particularly in the vicinity of the recirculation zone, which can be explained by the stabilization of the convective instability, increased viscosity in the post-flame gases and the vorticity sink induced by the gas expansion.

The experiments for the present test case have been carried out by the Volvo Company. The Validation Rig consists of a straight channel, divided into an inlet section and a combustor section. Triangular bluff-bodies were used for flame stabilization.

The simplicity of the geometry makes this test case an ideal platform for validation and verification of different numerical methods and mathematical models. A series of numerical simulations undertaken to study both non-reacting and reacting bluff-body flows are reported here. The purpose is to assess the applicability of different turbulence and combustion (turbulence-chemistry interaction) models to capture the unsteady (combustion) physics. Heat transfer effects are investigated as well. Different calculation approaches like RANS/URANS, LES and hybrid RANS/LES (SAS) and different turbulence models are compared. Results obtained by several turbulence-chemistry interaction models like TFC and EDC are compared and discussed as well.

|

| Schematic view of the flow mechanics of the non-reactive and reactive bluff-body flows. |

Contributed by: D.A. Lysenko and M. Donskov — 3DMSimtek AS, Sandnes, Norway

© copyright ERCOFTAC 2019